AUTOMATIONS

Process Management

SYSTEM AUTOMATION

Thanks to our experience, knowledge of plant engineering, and direct communication between client and technician, we can offer all these services with flexibility and rapid turnaround times.

- Safety management in plants in classified areas

- Production process control systems

- Supervision and implementation of in-line denaturation processes

- Visualize and define storage in warehouses and plants using GE iFix SCADA software

- Control structures and remote alarm communication systems

MANAGEMENT SYSTEMS

Here are some examples of the work we've done to meet our customers' needs.

Management Systems

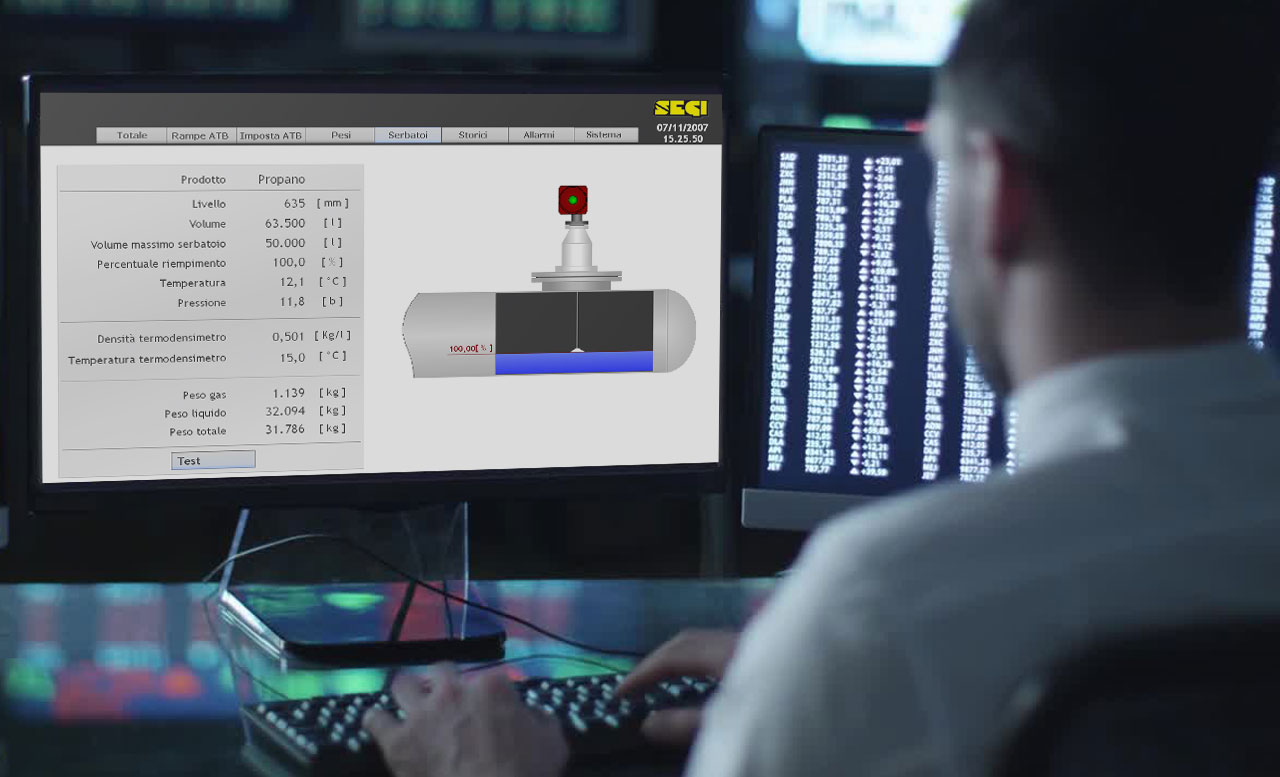

TANKS NETWORKS

The tank network management system was designed to meet our customers' requests and provide complete management and remote diagnostics of unattended remote sites.

Management Systems

FIRE PREVENTION AND AUTOMATIC VALVE TESTING

Fire protection system management plays a crucial role in ensuring safety. SEGI has implemented fully automated systems for many facilities: acquisition of field sensors, PLC control of the received data, and implementation of all necessary safety measures.

Management Systems

ADDITIVATION

The system was designed to comply with ministerial regulations (Directive 2003/96/EC and Resolution 2228 of 28/12/2007) regarding in-line denaturing. The regulation requires that the product, in this case LPG, be differentiated and identifiable in the event of inspection by officials based on its intended use, due to the different excise duties applied.

Management Systems

SCADA IFIX

SIGMA – Integrated Mass Management System SIGMA iFIX is an HMI/SCADA created by SEGI based on the iFIX package from GE Intelligent Platforms.

Management Systems

LEAK CHECK

During the loading/unloading phase of the product from the ship to the plant, the customer asked us to create a system capable of detecting any product leaks and activating the emergency systems in the event of problems.